Printed circuit boards (PCBs) are one of the core components of modern electronic devices. They integrate various electronic components through mechanical support and electrical connections, enabling complex circuit designs. The PCB industry involves a series of processes from design, manufacturing to testing, with high technical content and strict process requirements. Its quality directly affects the performance and reliability of the final product. To showcase our production capabilities and product quality, our sales manager Peter, along with sales representatives Xiao Fang Xie and Rosa, guided a customer from Iran on a tour of our PCB factory yesterday. This visit not only demonstrated our technical strength but also deepened the customer's trust and recognition of our company in PCB industry.

Initial Introduction

The tour began in a conference room where Peter and his colleagues warmly welcomed the customer and briefly introduced the company's history, scale, and main products. Peter then detailed the itinerary of the visit, including various production line stages of PCB products, quality control processes, and the final testing and packaging procedures. This session provided the customer with an overview of the company's overall strength and laid a solid foundation for the upcoming factory tour.

Tour Process

Raw Material Inspection

Before entering the production workshop, Peter led the customer to the raw material inspection area. This area stores a large amount of copper foil, substrate materials, and chemical reagents. Peter explained that high-quality raw materials are the foundation of manufacturing high-quality PCB products. Therefore, we strictly control the quality of each batch of raw materials, using advanced instruments and equipment to ensure that all materials meet the standards.

Production Workshop

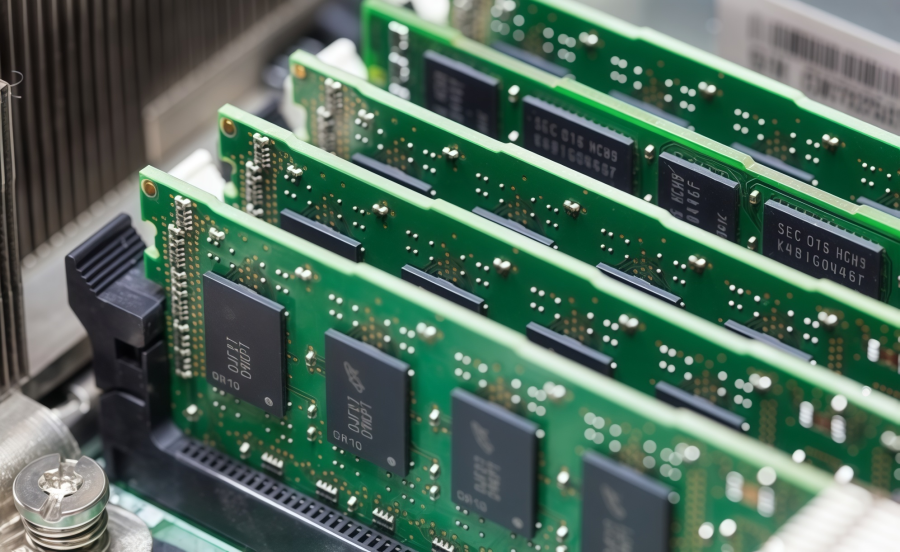

Next, the customer walked into the production workshop, which is the core area of the entire factory. Various modern production equipment is neatly arranged, and workers in clean uniforms focus on operating their respective equipment. Peter and the sales representatives introduced each production stage to the customer:

Pattern Transfer: This is the process of transferring the designed circuit pattern onto the substrate. Peter explained that we use advanced photolithography technology to ensure high precision and consistency of the patterns for PCB products.

Etching: In this stage, unwanted copper is removed through chemical etching to form the conductive patterns of the circuit. Peter emphasized that each step of the etching process is strictly controlled to ensure the quality of the circuit boards in PCB industry.

Drilling and Plating: This is the process of drilling connection holes on the substrate and performing plating in PCB industry. Peter mentioned that our drilling equipment has high precision to meet the needs of various complex circuits, while the plating process ensures the conductivity of the circuit boards.

Lamination and Soldering: This involves stacking and soldering multiple layers of circuit boards. Peter pointed out that this stage has a high technical content, and our technical team has rich experience to ensure that each layer is perfectly aligned.

Quality Control

During the tour, Peter particularly emphasized the importance of quality control. They led the customer to the quality inspection department, showcasing how we ensure product quality through a series of rigorous tests in PCB industry. Engineers here use high-power microscopes, electrical performance testers, and X-ray inspection equipment to meticulously inspect each PCB board. Peter explained that our goal is to achieve zero defects, ensuring that every PCB products leaving the factory meets customer requirements.

Finished Product Display

The final stop of the tour was the finished product display area for PCB products. Here, various types of PCB products are exhibited, including single-layer, multi-layer, and flexible boards. Peter mentioned that our products are widely used in industrial control, medical equipment, aerospace, military, automotive electronics, and other fields. The customer showed great interest and inquired about many technical details, which Peter and the sales representatives patiently answered, giving the customer a deeper understanding of our PCB board products.

In-depth Analysis of Customer Needs

Why Overseas Customers Request Factory Visits

Customers developed through the Munich exhibition are interested in gaining an in-depth understanding of our company. They want to visit the factory to observe its scale, types and quantities of machines, and the quality and detail control of the PCB board production process, as well as assess the production environment. This reassures them about choosing our high-quality products and services.

Our PCBA Strength

We are a PCB manufacturer with over 20 years of experience in surface mount technology (SMT) production and ISO9001 quality certification in PCB industry. We have six mature production lines that can independently complete the entire series of processes, including PCB board bonding, printing, SMT, and testing, within our own factory, boasting advanced manufacturing capabilities in the industry.

The Key to Sustained Customer Cooperation

Quality control is crucial in PCB board manufacturing. From raw material inspection to every step of the production process, and finally to electrical performance testing and visual inspection, every stage must be strictly controlled. Advanced inspection equipment and technology are essential. The complexity of the SMT process and high-quality detail control are key to gaining customer trust, ensuring they confidently choose our PCB board. Additionally, many engineering adjustments are involved, making customers hesitant to switch suppliers due to the time-consuming nature of re-communication.

Customer Feedback and Outlook

After the tour, the customer had a meeting with Peter in the conference room. They expressed high praise for the factory's advanced equipment, strict quality control, and professional technical team. The customer mentioned that the visit not only showcased the company's strength but also strengthened their confidence in long-term cooperation with us.

In his concluding remarks, Peter stated that customer recognition is the greatest encouragement for us. We will continue to adhere to high standards in production and management, striving to provide the best products and services for our customers. He also looks forward to more opportunities for in-depth cooperation with customers in the future, jointly promoting the development of the PCB industry.

Conclusion

Through this factory tour, the customer gained a direct understanding of our PCB products and experienced our company's excellence in technology development and quality control in PCB industry. This visit not only solidified our cooperative relationship with the customer for PCB board but also laid a solid foundation for future business expansion. We believe that with joint efforts, our cooperation will become even closer, and the prospects will be even brighter.

Any question or inquiry, pls feel free to contact us: [email protected]