26/01/28

G215HVN01.1 TFT-LCD – High-Resolution & Stable Display

AUO G215HVN01.1 is a 21.5-inch a-Si TFT-LCD display module developed by AU Optronics (AUO), designed for industrial display applications.In terms of display performance, the G215HVN01.1 supports Full HD resolution (1920 × 1080) and displays 16.7 million colors (RGB 8-bit), meeting the basic requirements for clarity and color depth in industrial monitoring, human–machine interface (HMI), and information display systems. The module uses a dual-channel LVDS interface for signal transmission, offering strong compatibility and easy integration with mainstream industrial motherboards and control systems.This article aims to provide a systematic overview and technical analysis of the AUO G215HVN01.1 industrial TFT-LCD module, helping engineers, purchasers, and solution designers quickly understand its key specifications, performance characteristics, and application value. G215HVN01.1 Key SpecsWe will introduce the core technical specifications of the G215HVN01.1 display module, including screen size, resolution, color depth, interface type, and more. You can also refer to the G215HVN01.1 datasheet for detailed information.Parameter ValueBrandAUOModelG215HVN01.1Size21.5"Compositiona-Si TFT-LCD, LCMResolution1920×1080Luminance250 cd/m² (Typ.)Contrast Ratio5000:1 (Typ.) (TM)Viewangle89/89/89/89 (Typ.)(CR≥10)Color Depth16.7M 72% NTSCLight Source10S7P WLED , 30K hours , With LED DriverInterface TypeLVDS (2 ch, 8-bit) , 30 pins ConnectorActive Area476.64(W)×268.11(H) mmPixel FormatRGB Vertical StripeFrame Rate60HzTouchscreenWithoutVoltage Supply5.0V (Typ.)Outline Size495.6(W) × 292.2(H) × 11.7(D)Max RatingsOperating Temperature: 0 ~ 60 °C ; Storage Temperature: -20 ~ 60 °C Learn more details: G215HVN01.1 Datasheet PDF(Contact us for a quote) G215HVN01.1 Signal DescriptionThe module using a pair of LVDS receiver SN75LVDS82(Texas Instruments) or compatible. LVDS is a differential signal technology for LCD interface and high speed data transfer device. Transmitter shall be SN75LVDS83(negative edge sampling) or compatible. The first LVDS port(RxOxxx) transmits odd pixels while the second LVDS port(RxExxx) transmits even pixels. LVDS Odd Data InputsRXinO0± (Pins 1, 2): LVDS differential data input (Odd data)RXinO1± (Pins 3, 4): LVDS differential data input (Odd data)RXinO2± (Pins 5, 6): LVDS differential data input (Odd data, H-Sync, V-Sync, DSPTMG)RXinO3± (Pins 10, 11): LVDS differential data input (Odd data) LVDS Odd Clock InputRxOCLKIN± (Pins 8, 9): LVDS differential clock input (Odd clock) LVDS Even Data InputsRXinE0± (Pins 12, 13): LVDS differential data input (Even data)RXinE1± (Pins 15, 16): LVDS differential data input (Even data)RXinE2± (Pins 18, 19): LVDS differential data input (Even data)RXinE3± (Pins 22, 23): LVDS differential data input (Even data) LVDS Even Clock InputRxECLKIN± (Pins 20, 21): LVDS differential clock input (Even clock) Power and GroundGND (Pins 7, 14, 17, 24): Power groundVDD +5V (Pins 28, 29, 30): Power supply input No ConnectionNC (Pins 25, 26, 27): No connection (for AUO testing only; do not connect)(Contact us for a quote) G215HVN01.1 Benefits & LimitationsWhen choosing an industrial display, it is important to understand its core benefits and physical limitations. The G215HVN01.1 offers excellent performance, but it also has certain technical limits in specific environments. This section will analyze the pros and cons of this model from several perspectives to help you understand its performance in real-world applications.BenefitsThe G215HVN01.1 uses advanced AMVA3 technology, and its best feature is a very high 5000:1 contrast ratio. The screen has 1920 x 1080 (FHD) resolution and a wide viewing angle of 89° from all sides. This allows users to see clear images from different positions. It includes a built-in WLED driver, which makes it easier to set up the hardware. Also, it features 72% NTSC color and an anti-glare surface. These features provide great visual quality for industrial displays and monitors.LimitationsAlthough this model performs well indoors, its typical brightness is only 250 cd/m². This limits its visibility under direct strong light. Also, as a VA-type panel, it has very high contrast, but its response time (typically 20/5 ms) is slower than high-speed gaming panels. Therefore, it is not suitable for applications that require extremely high dynamic refresh rates.(Contact us for a quote) G215HVN01.1 Functional Block DiagramThe following diagram shows the functional block of this model.From the functional block diagram, the signal processing of the G215HVN01.1 starts at the LVDS input interface. The external mainboard inputs video signals to the module through the LVDS connector while providing a +5V VDD power supply. The LVDS signals first enter the LVDS Receiver inside the AUO ASIC, where high-speed differential signals are converted into parallel data. The Timing Controller then organizes and distributes the image data, providing precise row and column control signals to the Source Driver (column driver) and Gate Driver (row driver), enabling line-by-line scanning and display on the TFT-LCD panel.For power management and display quality control, the module integrates a DC/DC Converter and Gamma Correction circuitry. The DC/DC converter converts the input voltage into multiple working voltages required by the panel and driver ICs, while the gamma correction circuit finely adjusts the grayscale voltage to ensure smooth brightness transitions and uniform, stable color reproduction. The backlight uses a separate LED Driver Board powered by VLED (+12V), providing stable driving for the LED backlight strips and ensuring reliable overall brightness output.(Contact us for a quote) G215HVN01.1 Application FieldsWith its strong technical advantages, the G215HVN01.1 has become the top choice for display solutions in many industries, especially in the industrial field. The following are the main applications for this display screen: 1. Industrial Automation Control PanelsThe G215HVN01.1 is commonly used in human-machine interface (HMI) displays for industrial automation equipment, providing high-resolution visualization of real-time production data and control status. Its clear image and stable color output allow operators to quickly assess equipment performance.l CNC machine displaysl Assembly line monitoring panelsl Packaging equipment control interfaces 2. Industrial Inspection and Measurement SystemsIn quality inspection and precision measurement systems, this module can display high-definition images and charts, helping engineers perform accurate analysis. Its high contrast and gamma correction ensure clear and reliable data visualization.l X-ray inspection machine displaysl Industrial microscope screensl Optical inspection system interfaces 3. Instrumentation DisplaysThe G215HVN01.1 is suitable for various instrumentation equipment, used to display parameters, waveforms, or experimental data. Its high refresh rate and stability support long-term operation and continuous display.l Power monitoring instrumentsl Laboratory data acquisition devicesl Environmental monitoring terminals 4. Smart Manufacturing and Industrial RobotsIn smart manufacturing systems and industrial robot control terminals, this module provides a clear real-time interface to support monitoring and adjustment of complex tasks.l Robot operation panelsl Smart assembly line monitoring screensl Automated sorting system interfaces 5. Industrial Transportation and Logistics ControlThe G215HVN01.1 can be applied in industrial transportation and logistics control systems, displaying transport status, routing information, and system alerts to provide operators with an intuitive interface.l Industrial vehicle monitoring displaysl Port loading and unloading control terminals(Contact us for a quote) G215HVN01.1 Operating Precautions1. The front polarizer is fragile; avoid scratches.2. Turn off power before connecting or disconnecting the input connector.3. Remove water immediately to prevent discoloration or stains.4. Clean the panel only with soft cloth or absorbent cotton.5. The glass panel may crack if dropped or hit.6. Handle with ESD protection; ensure proper grounding.7. Do not open or modify the module.8. Do not press the rear reflector sheet.9. When repacking, press only the ends of the LED reflector gently—never the center.10. Do not rotate or tilt the signal interface connector during insertion or removal.11. Do not twist or bend the module; design the product to prevent external force.12. Use a power supply compliant with Limited Power Source standards.13. Extreme temperatures may affect brightness and response time.14. Prolonged high-temperature operation reduces LED lifespan and luminance.15. Specifications apply when the module is used in landscape orientation.16. Avoid long-term static images; use screen savers or moving content to prevent image sticking.(Contact us for a quote) ANDE Electronics: Reliable LCD Display SolutionsAs a professional display supplier, Ande Electronics is committed to providing LCD modules that meet modern application needs.We offer not only high-quality display products but also reliable technical support and flexible purchasing options. Our experienced engineering team works closely with customers to provide guidance on module selection, integration, and optimization.Choosing Ande Electronics, then engineers and manufacturers will gain a partner focused on quality, innovation, and efficiency.

161

26/01/23

24LC08BT-I/OT EEPROM Guide: Pinout, Features & Applications

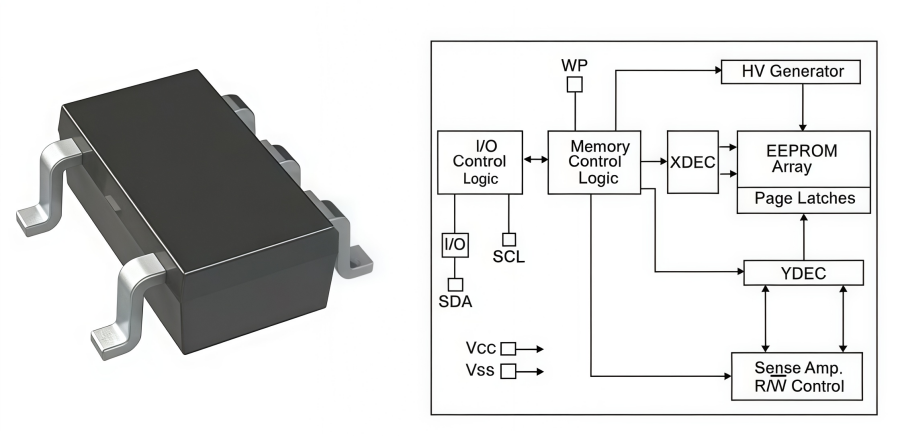

24LC08BT-I/OT OverviewThe 24LC08BT-I/OT is an 8 Kbit serial EEPROM from Microchip Technology. It uses an I²C (two-wire) interface. The memory is organized into four blocks, each with 256 × 8 bits, which makes addressing and memory management simple.In terms of electrical features, the 24LC08BT-I/OT supports a wide operating voltage range from 2.5 V to 5.5 V. This allows it to work easily with many microcontrollers and low-power systems. The device has very low standby current in the microamp range and active current in the milliamp range, helping reduce total system power use. It also supports page write operations of up to 16 bytes, which improves write speed while keeping data reliable.For applications, the 24LC08BT-I/OT is commonly used for device parameter storage, calibration data, configuration settings, and serial number storage. It is widely used in consumer electronics, industrial control systems, medical devices, and IoT products. 24LC08BT-I/OT Key SpecsParameterValuePart Number24LC08BT-I/OTDescriptionIC EEPROM 8K I2C 400KHZ SOT23-5Lead Free Status / RoHS StatusLead free / RoHS CompliantMemory Size8Kb (256 x 8 x 4)Clock Frequency400kHzWrite Cycle Time - Word, Page5msBase Part Number24LC08TechnologyEEPROMMemory TypeNon-VolatilePackageSOT-23-5Memory InterfaceI²CMoisture Sensitivity Level (MSL)1 (Unlimited)Voltage - Supply2.5 V ~ 5.5 VAccess Time900nsOperating Temperature-40°C ~ 85°C (TA)(Contact us for a quote) 24LC08BT-I/OT PinoutThe 24LC08BT-I/OT EEPROM in the SOT-23 package has a simple 5-pin configuration.SCL (Serial Clock): This pin is used to provide the clock signal for the I²C interface. It synchronizes data transfer between the EEPROM and the microcontroller.VSS (Ground): This is the ground reference for the device and should be connected to the system ground.SDA (Serial Data): The data line for I²C communication. It carries the read and write data between the EEPROM and the controller.VCC (Supply Voltage): This pin provides the power for the EEPROM and supports a wide voltage range, typically 2.5 V to 5.5 V.WP (Write Protect): This pin controls write protection. When pulled high, the memory is protected against write operations. When low, writing is allowed.(Contact us for a quote) 24LC08BT-I/OT Features• Single Supply with Operation down to 1.7V for 24AA08 and 24FC08 Devices, 2.5V for 24LC08B Devices• Low-Power CMOS Technology:- Read current 1 mA, maximum- Standby current 1 µA, maximum (I-temp.)• 2-Wire Serial Interface, I2C Compatible• Schmitt Trigger Inputs for Noise Suppression• Output Slope Control to Eliminate Ground Bounce• 100 kHz, 400 kHz and 1 MHz Compatibility• Page Write Time: 5 ms, Maximum• Self-Timed Erase/Write Cycle• 16-Byte Page Write Buffer• Hardware Write-Protect• ESD Protection >4,000V• More than 1 Million Erase/Write Cycles• Data Retention >200 Years• Factory Programming Available• RoHS Compliant• Temperature Ranges:- Industrial (I): -40°C to +85°C- Extended (E): -40°C to +125°C• Automotive AEC-Q100 Qualified(Contact us for a quote) 24LC08BT-I/OT Block DiagramThis block diagram of the 24LC08BT-I/OT can be easily understood from two perspectives: data transfer and core memory storage.1. Data Input and Control LogicThis part acts as the chip’s “brain” and “external window.” The SDA and SCL pins communicate with the external host through the I/O Control Logic. When a command is received, the Memory Control Logic determines whether to read or write data. The WP pin at the top of the diagram functions like a physical lock, preventing accidental data modification when enabled. The HV Generator is a specialized tool for the memory, generating the high voltage needed to program or erase data in the non-volatile storage medium. 2. Addressing and Memory ArrayThe EEPROM Array is the core area where data is stored. To locate a specific data point, the control logic sends instructions to the XDEC and YDEC, which act like coordinates to precisely select a location in the array. Before data enters or leaves the array, it is temporarily stored in the Page Latches. Then, the Sense Amplifier and R/W Control at the bottom amplifies the signals, ensuring that even weak signals can be read or written accurately.(Contact us for a quote) 24LC08BT-I/OT Application Fields1. Consumer ElectronicsThe 24LC08BT-I/OT is mainly used to store user settings. For example, in smart TVs or monitors, it saves brightness, contrast, volume levels, and preset channel lists. 2. TelecommunicationsIt is used in routers, switches, or optical modules. It stores fixed data like MAC addresses, device serial numbers, and vendor IDs. It also keeps specific port configurations and firmware update flags. 3. Automotive ElectronicsThanks to its industrial-grade stability, it is used in dashboards or in-car infotainment systems. It stores key driving data, initial sensor calibration values, and fault codes (DTC) for safety systems like airbags. 4. Industrial Control & AutomationIn PLCs and various industrial sensors, it stores calibration curves and range parameters after on-site setup. It can also record total operation time or error codes from abnormal shutdowns. 5. PC & PeripheralsThis chip is widely used in printer cartridges, graphics cards, and docking stations. In printer cartridges, it stores the remaining ink level and serial number to prevent counterfeiting. In graphics cards, it reports key hardware information such as memory frequency and timing to the system through the SPD function. 6. Smart Home & IoTIn smart plugs, thermostats, or cameras, it stores connection credentials. It keeps Wi-Fi SSID and passwords, unique cloud authentication keys, and user-set automation schedules.(Contact us for a quote) 24LC08BT-I/OT PackageThe 24LC08BT-I/OT uses a SOT-23 (5-Lead) package design. While it provides high-performance storage, it is also very small. This saves a lot of space on the circuit board. Because of its tiny size, it can easily fit into portable devices and high-density electronic modules. ANDE Electronics: Your Trusted Partner in Electronic Component Sourcing At ANDE Electronics, we make getting the electronic components you need simple and fast. We work directly with top global manufacturers to provide high-quality components that have passed our strict checks, so you can count on them for your projects.We also focus on quick and consistent delivery to keep your work on schedule and avoid delays. When you need reliable and efficient electronic parts for your projects, ANDE Electronics is a partner you can trust.

280

26/01/22

Drones with Best Image Sensors: Navigation & Perception

As drone technology continues to mature, these aerial platforms are changing many industries with efficient and flexible solutions. In agriculture, drones support precision farming, crop monitoring, and livestock tracking. In industry, drones are used for site surveys, infrastructure inspection, and project monitoring. In logistics and public services, drones are also transforming delivery methods. To ensure superior data quality and safety, developers are increasingly prioritizing drones with best image sensors.Among many key technologies, autonomous navigation and perception systems are the foundation of intelligent and safe drone flight. By combining multiple sensing methods, drones can detect their surroundings in real time and perform positioning and path planning. Image sensors play a critical role in environment recognition, object detection, and visual navigation. This article focuses on how these drone systems are implemented and the role of image sensors for it. Typical Applications of DronesDrone technology is rapidly expanding across many industries. From mapping and inspection to agriculture and logistics, drones are no longer just aerial cameras but efficient work platforms with intelligent systems. The following sections introduce typical drone applications and their use in different industries. 1. Mapping DronesMapping drones are typically equipped with high-resolution cameras and depth-sensing sensors. They are used to collect accurate geographic data and generate high-precision maps and 3D models. Common applications include construction planning, mining surveys, and environmental monitoring. 2. Inspection DronesInspection drones integrate thermal imaging devices and various sensors to examine infrastructure such as bridges, power lines, and pipelines. They can collect real-time data and quickly detect potential issues like cracks and corrosion. 3. Agricultural DronesAgricultural drones use multispectral sensors to monitor crop growth conditions. They support irrigation management, pest and disease detection, and precise spraying of pesticides and fertilizers, driving the development of modern precision agriculture. 4. Delivery DronesDelivery drones are designed primarily for cargo transport. They are used in logistics, healthcare, and e-commerce, enabling fast material delivery while improving efficiency and reducing labor costs. 5. Surveillance and Security DronesThese drones are equipped with high-definition cameras and thermal imaging systems. They can monitor large areas continuously and detect abnormal activities or intrusions, enhancing overall security. 6. Heavy-Lift DronesHeavy-lift drones feature strong payload capacity. They are suitable for transporting materials and equipment in construction, disaster response, and logistics applications, meeting demanding operational needs. 7. Environmental Monitoring DronesEnvironmental monitoring drones are used to collect data on air quality, water conditions, and wildlife activity. They provide reliable data for ecological research, environmental protection, and resource management. 8. Emergency Response DronesIn disaster and emergency situations, emergency response drones can deliver medical supplies, search for survivors, and assess damage. Combined with thermal imaging and loudspeaker systems, they help improve rescue efficiency. 9. Construction DronesConstruction drones are widely used for site surveys, construction progress tracking, and safety inspections. By providing real-time data and high-resolution imagery, they enable more efficient project management and decision-making.(Contact us for a quote) UAV Autonomous Navigation SystemImage and depth sensors are key electronic parts of a drone's navigation system. They provide the important data needed for the drone to sense its environment. Image sensors help drones navigate by recognizing and tracking visual markers, which is very useful in places where GPS is not available. With these sensors, drones can detect obstacles, follow planned routes, and adjust their flight based on real-time visual data.The visual data from image sensors is processed by advanced computer vision algorithms. That allows drones to understand complex scenes and make smart decisions. At the same time, depth sensors send out laser pulses and measure the reflection time, and create a precise 3D map of the surrounding environment.By combining image and depth data through sensor fusion, drones can safely fly through complex terrain even in low light or visually challenging conditions. The combination of visual and depth sensing improves the drone's situational awareness. It enables obstacle avoidance, precise navigation, and autonomous decision-making, which are crucial for reliable operation in diverse environments.GPS navigation is another important technology for drones. It works by receiving signals from satellites and calculating the drone's exact position. GPS guides the drone to follow set waypoints. However, in places like indoors, dense forests, or urban canyons with tall buildings, GPS signals can be weak or lost. By combining GPS with image and depth sensors, drones can switch smoothly between different navigation methods and maintain accurate positioning even when GPS signals are weak or unavailable.(Contact us for a quote) Drone Perception SystemWhen choosing image sensors for a drone, it is essential to consider the specific application and requirements. A drone system typically uses six to eight sensors, but in some cases, up to twelve sensors may be deployed.Global shutter sensors capture the entire frame at once, making them ideal for imaging moving objects. They effectively prevent image distortion and motion artifacts, which is crucial for high-precision tasks such as mapping, surveying, and industrial inspection. By capturing the full frame in a single shot, global shutters eliminate common issues like the “jello effect” and motion blur seen in rolling shutter sensors.l Low-power image sensors: Consume less energy, making it easier to deploy multiple sensors for a comprehensive view of the scene.l High Dynamic Range (HDR) cameras: Capture clear, detailed images under varying lighting conditions.l High resolution: Higher pixel counts enhance the drone’s capability, enabling more precise and detailed inspections and surveys.l Extended vision: SWIR (Short-Wave Infrared) sensors allow observation beyond the visible light range.(Contact us for a quote) Ande Electronics: Your Partner for Intelligent Drone UpgradesAs a trusted partner for intelligent drone upgrades, Ande Electronics offers a wide range of electronic components, including high-quality image sensors. These sensors are not only widely used in drone perception systems but also find applications in autonomous driving, security surveillance, industrial automation, smart robotics, and smart city projects. With advanced technology and strict quality control, Ande Electronics’ sensors meet the demands of diverse applications for accuracy, reliability, and high performance, providing dependable electronic solutions across industries.Start your journey with Ande today and leverage our selection to build drones with best image sensors that deliver clear and precise visual data, enabling efficient, safe, and intelligent application upgrades.

182

26/01/21

M315DJJ-K31 4K LCD Panel: Applications & Review

As the demand for high-resolution displays continues to grow in industrial, medical, and commercial applications, LCD technology is constantly evolving. Innolux M315DJJ-K31 is a 32.0’’ a-Si TFT-LCD display panel. It features a WLED backlight unit and a 51-pin interface using the 8-lane V-by-One high-speed data interface. This module supports UHD resolution up to 3840 × 2160 and can present rich visual effects with up to 1.073 billion colors.Unlike some integrated display modules, the M315DJJ-K31 requires an external converter for its backlight driver, which provides greater flexibility for system design. This article aims to provide a detailed introduction to the basic features, advantages, limitations, and applicable fields of the M315DJJ-K31, helping engineers and system designers quickly understand the technical specifications and application potential of this module. M315DJJ-K31 Technical SpecsWe will cover the key technical specifications of the M315DJJ-K31 display module, including screen size, resolution, color depth, interface type, and other features. For more detailed information, please refer to the M315DJJ-K31 datasheet.Parameter ValueBrandInnoluxModelM315DJJ-K31Size32"CompositionLCMResolution3840(RGB)×2160, UHD 139PPILuminance400 cd/m² (Typ.)Contrast Ratio3000 : 1 (Typ.) (TM)Viewangle89/89/89/89Color Depth1.07B 98% DCI-P3Light SourceWLED , 30K hours , No DriverInterface TypeV-by-One 8 lane , 51 pins ConnectorPixel FormatRGB Vertical StripeActive Area703.4(W)×397.85(H) mmFrame Rate60HzTouchscreenWithoutVoltage Supply12.0V (Typ.)Weight3.46±0.18KgsOutline Size717.4(W)×413.85(H)×18.9(D) mmMax RatingsOperating Temperature: 0 ~ 50 °C ; Storage Temperature: -20 ~ 85 °C Learn more details: M315DJJ-K31 Datasheet PDF(Contact us for a quote) M315DJJ-K31 Functional Block DiagramFrom the functional block diagram, it can be seen that the signal processing of the M315DJJ-K31 is centered around the V-by-One input interface. Differential data (RX0N–RX7P), control signals (HTPDN, LOCKN), power input (Vin), ground (GND), and no-connection pins (N.C.) from the external mainboard enter the module through the input connector. The V-by-One input signals are then sent to the Timing Controller, which organizes and distributes the image data, providing precise row and column control signals to the Scan Driver IC and Data Driver IC, thereby enabling line-by-line scanning and display on the TFT-LCD panel.Regarding power and backlight management, the block diagram shows that the DC/DC Converter & Reference Voltage Generator converts the input Vin voltage to the operating voltages required by the panel and driver ICs while providing stable reference voltages. The backlight is driven by a separate Backlight Unit, with VLED and ILED controlling the backlight voltage and current, achieving uniform and adjustable brightness. Overall, the functional block diagram clearly demonstrates the modular design concept of the M315DJJ-K31 in terms of signal processing, power management, and display driving.(Contact us for a quote) M315DJJ-K31: Advantages vs. LimitationsWhen choosing a high-resolution display, it is important to understand its core benefits and physical limitations. The M315DJJ-K31 offers exceptional performance, but it also has few technical limits. This section will analyze the pros and cons of this model from several perspectives to help you understand its performance in applications.AdvantagesThe most prominent advantage of the M315DJJ-K31 is its 3840 × 2160 (UHD) ultra-high-definition resolution, which provides users with an exceptional 4K visual experience and color performance. At the same time, it features 1.073B (10-bit) color depth, which prevents the common color banding issues found in lower-bit panels. Additionally, the use of an 8-lane V-by-One high-speed interface ensures stable data transmission for large amounts of information and effectively reduces electromagnetic interference (EMI) by using fewer wires.LimitationsAlthough this module has excellent display quality, its main limitation is the complexity of system integration. Unlike modules with built-in driver circuits, the M315DJJ-K31 requires an external converter for its backlight. This means system designers need to allocate extra space and design an independent power supply circuit.(Contact us for a quote) M315DJJ-K31: High-Resolution Desktop Monitor SolutionsIn the field of modern professional offices, 32 inches is widely considered the "golden size" for 4K resolution. The M315DJJ-K31 provides a 3840 × 2160 resolution with a pixel density of 139 PPI. This makes it perfect for handling complex Excel sheets, multi-window tasks, or writing code. For office workers who spend long hours in front of a screen, it effectively helps reduce eye fatigue.Beyond basic office work, this panel also performs well in creative design. Thanks to its 10-bit (1.073 billion colors) display technology, it effectively solves the common problem of color banding in design work. M315DJJ-K31: Reliable Industrial and Commercial DisplaysOn industrial production lines and in control rooms, display devices must not only be clear but also run stably. The M315DJJ-K31 uses a V-by-One interface designed for large data transmission. Its excellent anti-electromagnetic interference (EMI) features ensure that image signals remain stable, flicker-free, and undistorted, even in factories filled with motors and inverters.In commercial applications, 32 inches is an ideal size for human-machine interaction. Whether it is displaying medical images in digital consultation rooms or serving as a touch interface for bank kiosks, the typical brightness of 350 cd/m² fits most indoor lighting environments. M315DJJ-K31: Specialized Marine DisplaysIn the bridge and control rooms of ocean-going vessels, displays are critical for navigational safety. Recently, our M315DJJ-K31 was successfully integrated into a client’s marine computer display project. Given the complexity of open-sea navigation, equipment must withstand constant hull vibrations and harsh environments. Thanks to its stable structural design and excellent anti-interference capabilities, this panel ensures that radar charts and navigation data remain clearly visible in all types of extreme weather.Furthermore, the 4K UHD resolution and high contrast of the M315DJJ-K31 allow crew members to quickly capture critical alerts under varying light conditions. This real-world application proves the module's durability and professional performance in demanding maritime settings. M315DJJ-K31: Immersive Gaming and Entertainment DisplayThe M315DJJ-K31 has a native refresh rate of 60Hz. Although it is not a competitive e-sports screen, it has a natural advantage in immersive visual experiences. Its 3000:1 high contrast ratio far exceeds traditional IPS panels, making it great for playing 4K ultra-high-definition movies or beautiful console games.For home entertainment users, the sense of immersion from a large screen is irreplaceable. This module supports wide viewing angles. Even if family members sit to the side of the screen, they can share a clear picture without obvious color shifts or loss of brightness. As a cost-effective 4K solution, it balances high image quality with a great multi-user viewing experience.(Contact us for a quote) ANDE Electronics: Reliable LCD Display SolutionsAs a professional display supplier, Ande Electronics is dedicated to providing high-quality LCD modules for modern industry. Our products, such as the M315DJJ-K31, are widely favored and have received numerous positive reviews.Recently, a client selected the M315DJJ-K31 for a computer display of ocean-going vessels to deliver exceptional visual clarity during navigation. This 4K panel was successfully integrated into maritime technology, demonstrating Ande Electronics’ commitment to high quality and professional standards in every component we provide.In addition to premium products, we offer expert technical support and flexible procurement options to meet your specific needs. Whether you are working on industrial, medical, or automotive projects, our engineering team can assist with module selection and system integration. Partnering with Ande Electronics gives you a reliable expert, dedicated to ensuring your project is efficient and successful.

308

26/01/14

AT89S8253-24AU Microcontroller Overview: Pinout & Datasheet

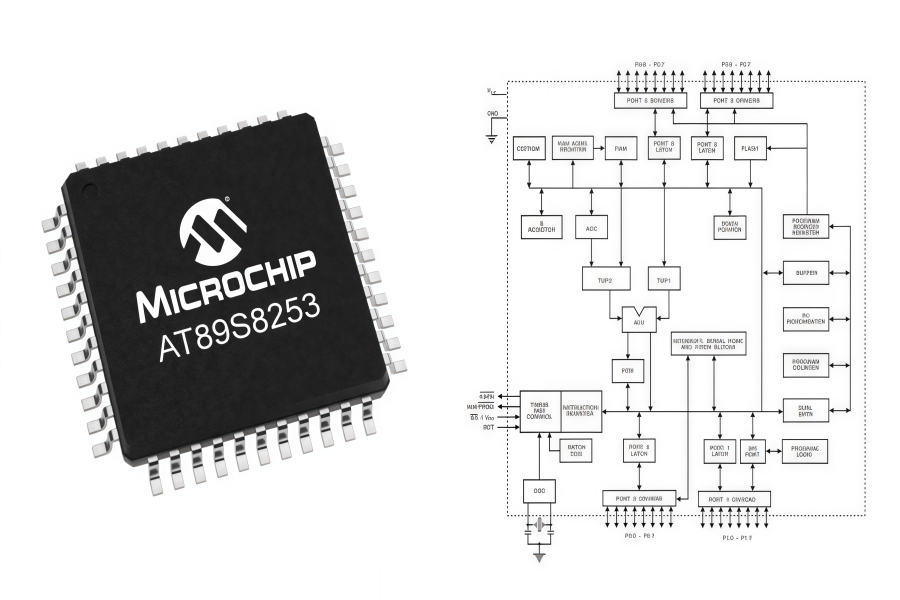

AT89S8253-24AU OverviewThe AT89S8253-24AU is a CMOS 8-bit microcontroller with 12KB In-System Programmable (ISP) Flash program memory and 2KB EEPROM data memory. It is built using high-density non-volatile memory technology and is compatible with the industry-standard MCS-51 instruction set and pin configuration. The on-chip downloadable Flash allows the program memory to be reprogrammed in-system through an SPI serial interface or a conventional non-volatile memory programmer.This microcontroller features 256 bytes of RAM, 32 programmable I/O lines, a watchdog timer, two data pointers, three 16-bit timers/counters, and a six-vector, four-level interrupt system. It uses static logic, allowing operation at zero frequency, and supports two power-saving modes: Idle Mode, which stops the CPU but keeps RAM, timers, serial port, and interrupts running; and Power-down Mode, which preserves RAM and freezes the oscillator until the next interrupt or reset.For programming, the on-chip Flash/EEPROM can be accessed via the SPI serial interface. When the RESET signal is held active, the SPI bus enters the serial programming mode, allowing the program memory to be read or written, unless one or more lock bits are set. AT89S8253-24AU Key SpecsParameterValuePart NumberAT89S8253-24AUDescriptionIC MCU 8BIT 12KB FLASH 44TQFPLead Free Status / RoHS StatusLead free / RoHS CompliantVoltage - Supply (Vcc/Vdd)2.7 V ~ 5.5 VOperating Temperature-40°C ~ 85°C (TA)Base Part NumberAT89S8253Core Size8-BitConnectivitySPI, UART/USARTSeries89SPackage44-TQFP (10x10)EEPROM Size2K x 8Oscillator TypeExternalNumber of I/O32RAM Size256 x 8Speed24MHzCore Processor8051PeripheralsPOR, WDTPackagingTrayMoisture Sensitivity Level (MSL)3 (168 Hours)Program Memory TypeFLASHProgram Memory Size12KB (12K x 8)(Contact us for a quote) AT89S8253-24AU PinoutThe AT89S8253-24AU comes in a 44-TQFP, with pin functions compatible with the standard MCS-51 microcontroller series. It features four 8-bit I/O ports (P0–P3), each usable for general-purpose input/output. The P0 port can serve as a multiplexed low-order address/data bus, while the P2 port provides high-order address output. The pins also include RST (reset), XTAL1/XTAL2 (crystal oscillator inputs), and special function pins for external interrupts and timer control, such as INT0/INT1 and T0/T1.In addition, the AT89S8253-24AU provides SPI interface pins (MOSI, MISO, SCK) to support in-system serial programming of the on-chip Flash. Other key control pins, such as EA/VPP, ALE/PROG, and PSEN, are used for program memory access selection, address latching, and external program reading, allowing flexible system design and enabling a variety of embedded control and peripheral expansion applications.(Contact us for a quote) AT89S8253-24AU Technical Features• Compatible with MCS®51 Products• 12K Bytes of In-System Programmable (ISP) Flash Program Memory– SPI Serial Interface for Program Downloading– Endurance: 10,000 Write/Erase Cycles• 2K Bytes EEPROM Data Memory– Endurance: 100,000 Write/Erase Cycles• 64-byte User Signature Array• 2.7V to 5.5V Operating Range• Fully Static Operation: 0 Hz to 24 MHz (in x1 and x2 Modes)• Three-level Program Memory Lock• 256 x 8-bit Internal RAM• 32 Programmable I/O Lines• Three 16-bit Timer/Counters• Nine Interrupt Sources• Enhanced UART Serial Port with Framing Error Detection and AutomaticAddress Recognition• Enhanced SPI (Double Write/Read Buffered) Serial Interface• Low-power Idle and Power-down Modes• Interrupt Recovery from Power-down Mode• Programmable Watchdog Timer• Dual Data Pointer• Power-off Flag• Flexible ISP Programming (Byte and Page Modes)– Page Mode: 64 Bytes/Page for Code Memory, 32 Bytes/Page for Data Memory• Four-level Enhanced Interrupt Controller• Programmable and Fuseable x2 Clock Option• Internal Power-on Reset• 42-pin PDIP Package Option for Reduced EMC Emission• Green (Pb/Halide-free) Packaging Option(Contact us for a quote) AT89S8253-24AU Block DiagramThe internal architecture (Block Diagram) of the AT89S8253 illustrates a typical 8051 core layout. From the logic block diagram, it can be seen that the chip integrates a high-performance ALU (Arithmetic Logic Unit) and multiple memory modules, including RAM for data buffering, FLASH for program code storage, and EEPROM for non-volatile data storage. Additionally, the architecture features an instruction register, a Stack Pointer, and a Program Counter, which, together with the Timing and Control unit, ensure efficient instruction decoding and execution.For external interaction and expandability, the architecture provides four 8-bit parallel interfaces (Port 0–3), each equipped with corresponding drivers and latches, supporting general-purpose I/O operations. To enhance communication and system reliability, the chip also integrates an SPI serial communication module, an interrupt system, and a Watchdog Timer, which effectively prevents program runaway and supports multi-device networking. At the bottom, the oscillator circuit (OSC) connects to an external crystal, providing precise clock timing for the entire MCU system.(Contact us for a quote) AT89S8253-24AU Applications1. Industrial Control SystemsThe AT89S8253-24AU can serve as the core MCU in industrial automation controllers, used for collecting sensor data, executing control algorithms, and driving actuators. It performs excellently in PLCs (Programmable Logic Controllers), temperature control systems, and automated production lines. 2. Smart Home DevicesThis MCU supports multiple communication interfaces and an interrupt system, making it suitable for integration into smart home devices for functions such as lighting control, automated curtains, or security monitoring. Its EEPROM can store user settings, enabling state recovery after power loss. 3. Data Acquisition and Measurement InstrumentsWith high-speed internal RAM and FLASH, the AT89S8253-24AU can collect and process various sensor data, such as temperature, humidity, and pressure, making it suitable for portable or laboratory measurement instruments. 4. Consumer ElectronicsThe MCU is compact and low-power, making it ideal as the control core for consumer electronics such as electronic toys, portable devices, and small home appliances. It can drive motors and buzzers via I/O interfaces to implement complex logic control and user interactions. 5. Communication and Networking DevicesThe AT89S8253-24AU integrates an SPI serial port, suitable for simple communication interfaces and network devices, enabling data transfer, protocol processing, and multi-device networking control. 6. Safety and Protection SystemsWith an integrated Watchdog Timer and interrupt system, the MCU is suitable for safety alarms and protection systems, ensuring reliable operation under abnormal conditions.(Contact us for a quote) ANDE Electronics: Your Trusted Partner in Electronic Component SourcingAt ANDE Electronics, we make getting the electronic components you need simple and fast. We work directly with top global manufacturers to provide high-quality components that have passed our strict checks, so you can count on them for your projects.We also focus on quick and consistent delivery to keep your work on schedule and avoid delays. When you need reliable and efficient electronic parts for your projects, ANDE Electronics is a partner you can trust.

394